Understanding Tapered Edges

Factory drywall edges are tapered, meaning they're thinner at the edge than in the field of the sheet. This creates a shallow depression when two sheets meet.

The depression exists specifically for taping. When you fill it with tape and compound, the result is flush with the surrounding surface. Brilliant design when you think about it.

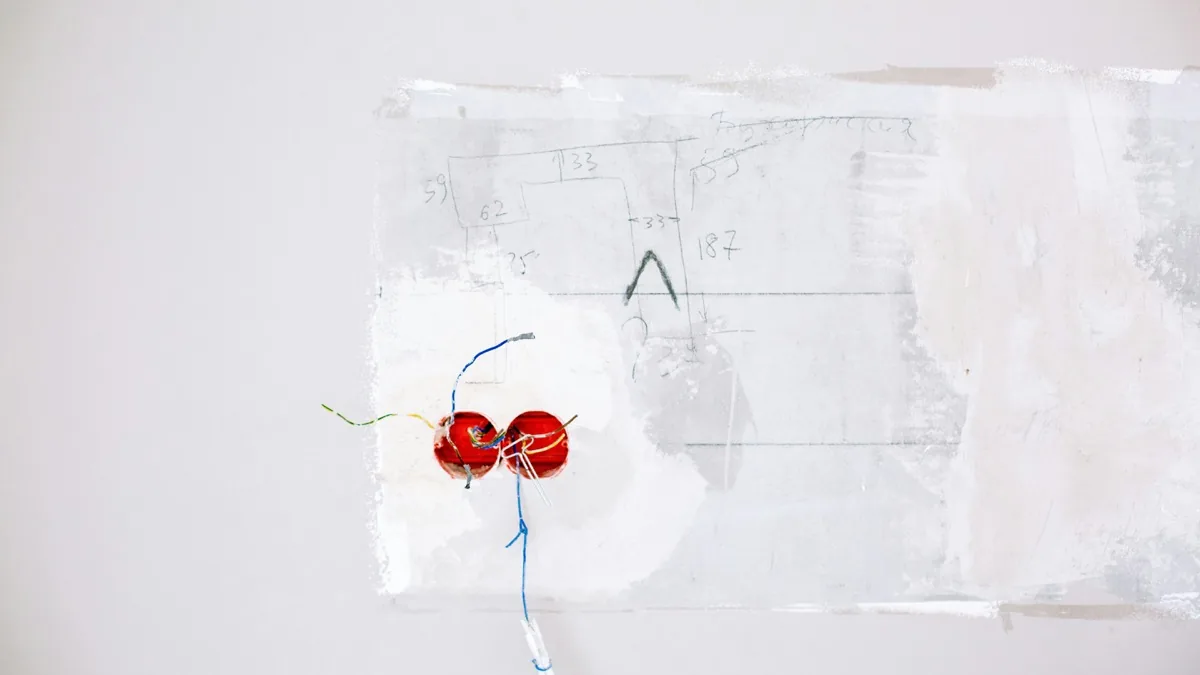

This is why layout planning matters. Position sheets so factory edges meet each other. When cut edges meet (butt joints), you lose the taper and face harder finishing.

The tapered edge is typically about 2 inches wide. Both sheets contribute their tapers, creating a trough about 4 inches wide and maybe 1/16 inch deep. Plenty of room for tape and compound.

The Bed Coat

Before tape goes on, compound goes on. This bed coat is what the tape sticks to.

Apply a thin, even layer of compound along the entire seam. About 4-5 inches wide, covering the tapered area. Consistency is key: too thick and you can't seat the tape properly, too thin and the tape won't bond.

Use the right compound consistency. Creamy, not stiff. If your compound is thick out of the bucket, add a little water and mix until it spreads smoothly.

Cover the whole length at once if possible. Stopping and starting can create variations that show through finishing.

Embedding the Tape

Lay paper tape on the wet bed coat, centering it over the seam. The tape should sit flat without gaps or lifts.

Using a 4 or 6 inch knife, press the tape into the compound starting from the center of the span. Work outward in both directions, pressing firmly to embed the tape and squeeze out excess compound.

You should see compound squeezing out from under both edges of the tape. If you don't, there's not enough bed coat or you're not pressing hard enough.

After initial embedding, make a final pass with firm pressure along the entire length. This seats the tape fully and removes air bubbles.

The embedded tape should lie flat with a thin layer of compound visible over it. The tape shouldn't feel loose if you press on it.

Finish Coats

After the first coat dries completely:

Light sand to knock down any ridges or high spots from the first coat. Just smoothing, not aggressive sanding.

Apply second coat wider than the first. Maybe 8-10 inches total width. You're building out from the tape, feathering the edges to blend into the surrounding wall.

The compound should be thickest directly over the tape, thinning gradually toward the edges. Use a wider knife than your first coat. The outer edges should be so thin they're nearly imperceptible.

Let dry. Light sand. Apply third coat even wider, maybe 12-14 inches. Same principle: thick center, feathered edges.

Final sanding brings everything to a smooth finish. Check with raking light to ensure transitions are invisible.

Common Flat Seam Problems

Problems I've encountered:

Tape bubbles: Insufficient bed coat or weak embedding pressure. The tape isn't bonded and lifts. Prevention is proper bed coat and firm pressure.

Visible seam ridge: Not enough feathering. The compound ends abruptly instead of gradually. Prevention is wider finish coats with true feathering.

Starved joint: Not enough compound over the tape. The tape pattern shows through. Prevention is ensuring adequate coverage before the first coat dries.

Cracked seam: Dried too fast, coating over wet material, or movement in the building. Prevention varies by cause.

Efficiency Tips

For rooms with multiple seams:

Do all bed coats and tape embedding at once. Work systematically around the room.

Let everything dry overnight. Trying to rush means uneven drying and problems.

Do all second coats at once, then all third coats. This creates consistent drying times across the room.

Sand between coats on the same day. You're already set up with sanding equipment.

This batch approach is how pros work. It minimizes setup and cleanup while keeping the project moving forward efficiently.