Measuring the Room

Start with the basics: length, width, and height of every surface you're covering.

Measure each wall separately. Opposite walls in the same room are often slightly different lengths. The room that's supposed to be 12x14 feet might actually be 12'2" by 13'10". Houses aren't as square as they look.

Note ceiling height at multiple points. Older homes especially can have ceiling heights that vary by an inch or more across a room. Measure in corners and in the middle.

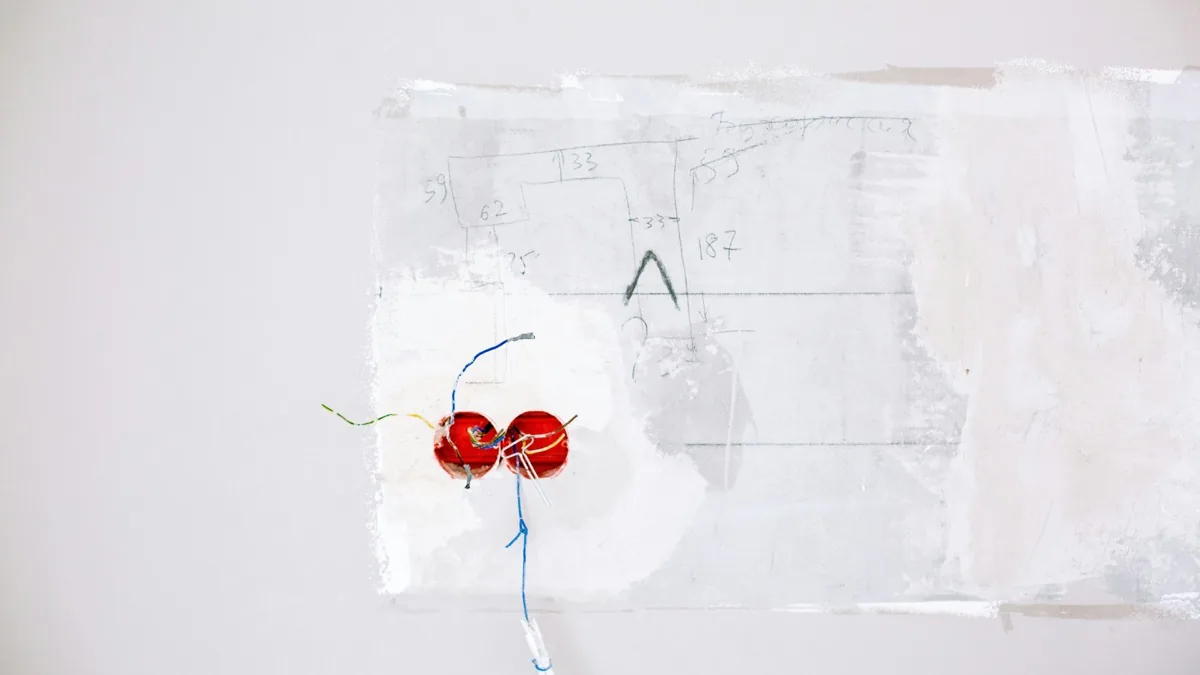

Mark obstacles on your sketch. Windows, doors, electrical panels, anything that interrupts the drywall. Note the dimensions and position of each obstacle.

Record everything. A quick sketch with measurements noted is worth more than trying to remember numbers. I use graph paper and make each square represent one foot.

Planning Ceiling Layout

Ceilings go first, so plan them first.

Run sheets perpendicular to joists. This crosses more joists, giving more fastening points.

Start from one wall and work across. Plan to end with cut pieces against the far wall rather than in the middle.

Use the longest sheets practical. 4x12 sheets create fewer seams than 4x8. Fewer seams means less taping and less chance of visible joints. But 4x12 sheets are heavy and unwieldy, so consider whether you can actually handle them.

Stagger end joints. If the first row ends with a seam 8 feet from the wall, start the next row with a cut piece so its first seam is offset by at least a few feet. This prevents continuous seam lines.

Planning Wall Layout

Walls have more complexity because of windows, doors, and electrical boxes.

Horizontal installation is standard. The long edge of the sheets runs horizontally. This puts the strongest joint (the factory-tapered edge) at a workable height and minimizes vertical seams.

Start from the top. The top row goes up first, tight to the ceiling. The ceiling edge doesn't need to be perfect because it's butted against the ceiling sheet.

Position seams strategically. Avoid having seams land right at door or window corners. These are stress points where cracks develop. If a seam would fall near a corner, adjust your layout to move it.

Work around large obstacles with full sheets. It's easier to cut around a window from a full sheet than to piece together multiple cuts. Plan which sheet covers which obstacle.

Calculating Materials

Once you have measurements and a layout sketch, calculate materials.

Square footage approach: Multiply height by perimeter of walls, add ceiling area. Divide total by 32 (the square footage of a 4x8 sheet) for number of sheets needed.

This gives a baseline. Then add for waste. Simple rectangular rooms, add 10%. Complex rooms with lots of cuts, add 15-20%.

Sheet-by-sheet approach: Actually count sheets on your layout sketch. This is more accurate but more time-consuming. For small jobs, it's worth doing.

Don't forget closets, soffits, and other small areas. They add up.

Factor in your mistakes. First-timers should add extra sheets because cuts won't all be perfect. Better to return unused sheets than to make another trip mid-project.

Material List Beyond Drywall

Sheets aren't the only material you need.

Screws: Roughly one pound of screws per 500 square feet of drywall. Better to have extra than to run out.

Tape: One 500-foot roll covers about 500 square feet of drywall. Get at least one full roll for most rooms.

Joint compound: About one gallon covers 100 square feet, but this varies with technique. Pre-mixed all-purpose is the safest bet for beginners.

Corner bead: Measure total linear feet of outside corners.

Sandpaper: Get a variety of grits. 120 for rough work, 150 for finishing, 220 for final smoothing.

Common Layout Mistakes

What goes wrong when people skip the planning:

Four corners meeting. When four sheet corners meet at one point, it's nearly impossible to tape flat. Plan your layout so sheets stagger and corners never align four-way.

Seams at stress points. Seams at window and door corners will crack eventually. Reposition sheets to move seams away from these spots.

Tiny pieces. A layout that requires 3-inch strips is harder to execute than one that uses full or half sheets. Adjust layout to avoid very small pieces.

Running out mid-project. Nothing kills momentum like stopping to buy more materials. Calculate carefully and buy slightly more than you think you need.

Wrong orientation. Sheets installed wrong direction create weaker joints and more taping work. Plan horizontal on walls, perpendicular to joists on ceilings.