Why Tape Fails

Drywall tape needs three things to bond properly: a wet bed coat of mud, firm pressure to embed the tape, and time to dry before the next coat. Skip any of these and you're setting up future failure.

Insufficient Bed Coat

This is the most common cause. The tape goes onto drywall that's either bare or has too thin a layer of mud. Without enough mud underneath, the tape has nothing to bond to. It might stick initially from the pressure of application, but over time it releases.

Proper technique is to spread a layer of mud about 1/8 inch thick along the seam, then press the tape into it. Mud should squeeze out on both sides of the tape when you run your knife over it. If no mud squeezes out, there wasn't enough to start with.

Not Enough Pressure

Laying tape on wet mud isn't enough. You need to press it firmly to embed the tape into the mud and squeeze out air bubbles. Every air bubble is a future failure point.

The proper technique is to embed the tape with a 4 or 6 inch knife, pressing firmly from the center outward on both sides. You should see mud squeezing out along the edges. Then run your knife the full length with firm pressure to smooth and embed.

Moisture Problems

Tape that gets wet after installation can lose its bond. Water damage, high humidity, or even painting before the mud was fully dry can cause release. The adhesion between paper tape and joint compound breaks down when saturated.

Fixing Bubbled Tape

For small bubbles where the tape is still attached on both sides, you might be able to salvage the existing tape. Might.

Score the bubble with a utility knife in an X pattern. Press down firmly on each flap to try to re-embed it. If the tape lays flat and feels solid, cover with a thin coat of mud and proceed with normal finishing.

More often, the bubble is a symptom of larger adhesion failure. If the tape feels loose when you press on areas around the bubble, or if the bubble immediately pops back up after pressing, the tape needs to come out.

Replacing Failed Tape

For peeling tape or extensive bubbling, the only real fix is replacement. Trying to glue down failed tape just delays the inevitable.

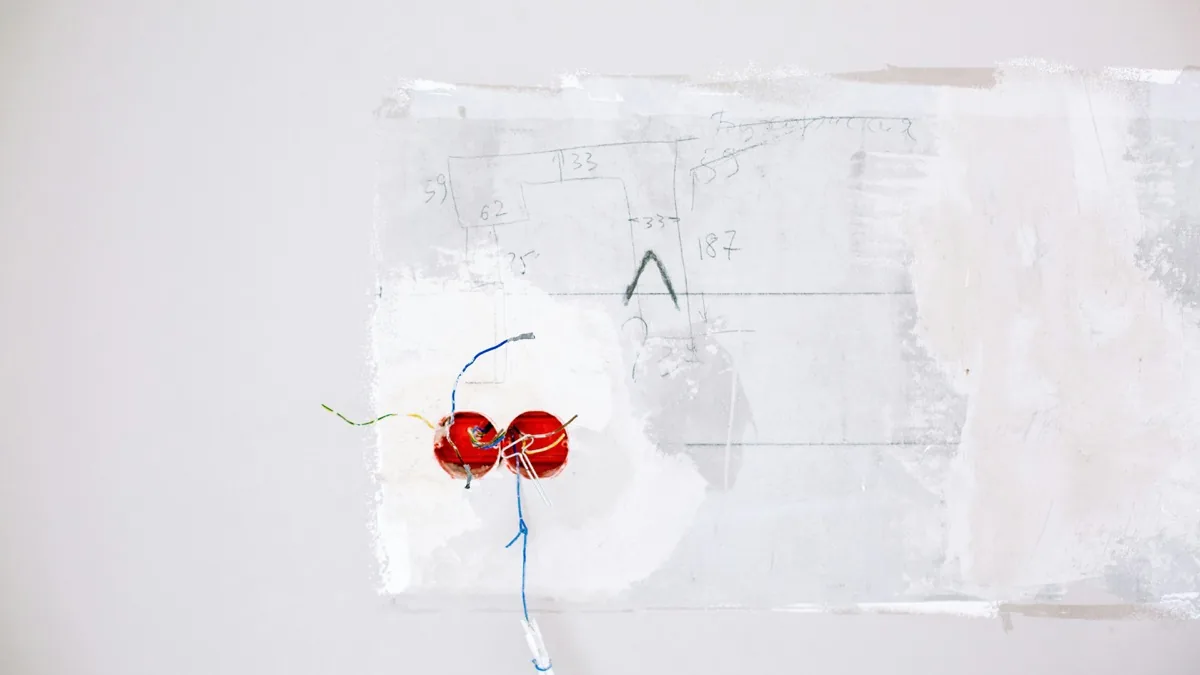

Step 1: Remove the Failed Section

Peel off all loose tape. Keep going until you reach tape that's solidly bonded. Use a utility knife to score the endpoints so you get a clean transition rather than a ragged edge.

Scrape off any dried mud that was under the tape. You want to get down to the drywall surface, or at least to solidly bonded compound. Use a 6-inch knife and don't be afraid to scrape firmly.

Step 2: Apply New Bed Coat

Spread joint compound along the exposed seam. I use setting compound for repairs since it bonds more aggressively than regular mud. Make sure you're covering the full width of where the new tape will go, plus an inch or so into the existing finished area on each end.

Don't skimp on the mud. The whole reason we're here is because there wasn't enough mud the first time. Apply about 1/8 inch thick, maybe a bit more.

Step 3: Embed New Tape

Cut a piece of paper tape to span the repair, overlapping the existing good tape by about 2 inches on each end. Press the tape into the wet mud, starting from the center and working outward.

Run your knife firmly along the tape to embed and squeeze out excess mud. You should see mud coming out on both sides. Feather those edges. Don't leave ridges of squeezed-out compound that will show through the finish coats.

Step 4: Let It Dry Completely

This is critical. The bed coat needs to be fully dry before you add finish coats. With setting compound, that's usually 45-90 minutes depending on the type. With regular mud, give it 24 hours.

I've rushed this step before and ended up with bubbles in my repair. Don't make my mistake. Go do something else and come back when it's actually dry.

Step 5: Finish Coats

Apply thin finish coats, feathering out 6-8 inches on each side. Two to three coats is typical. Sand lightly between coats once dry. The goal is to blend the repair invisibly into the surrounding wall.

Prime the repair before painting. Repaired areas absorb paint differently and will flash if not primed.

Paper Tape vs Mesh Tape for Repairs

Mesh tape is tempting for repairs because it's self-adhesive and easier to apply. You just stick it on and mud over it. No wet bed coat needed.

The problem is that mesh tape is weaker in tension than paper tape. For ceiling repairs or areas prone to movement, mesh tape is more likely to fail. The ceiling seam I repaired originally had mesh tape, which contributed to its failure.

Uncle Frank's rule, which has served me well: paper tape for flat seams and ceilings, mesh tape only for inside corners where the flexibility is actually helpful. For repairs, default to paper tape.

That said, if the original installation used mesh tape and it's only failed in one small area, matching with mesh tape is fine. Just don't upgrade a mesh installation to paper in spots since the different flexibility can cause problems at the transition.

Preventing Future Tape Failure

If you're doing new work or extensive repairs, set yourself up for success:

Proper bed coat every time. No shortcuts. Spread the mud, lay the tape, embed it firmly. If you don't see mud squeezing out, add more and try again.

Let it dry. Seriously. Overnight for regular mud. This is the step that gets skipped most often, and it's probably the most important.

Climate matters. Don't tape in very humid conditions or when temperatures are below 50 degrees. Both affect curing and can compromise the bond.

Pre-fill gaps. If your drywall seams have gaps larger than 1/8 inch, fill them with compound and let it dry before taping. Tape bridging big gaps is more likely to fail.